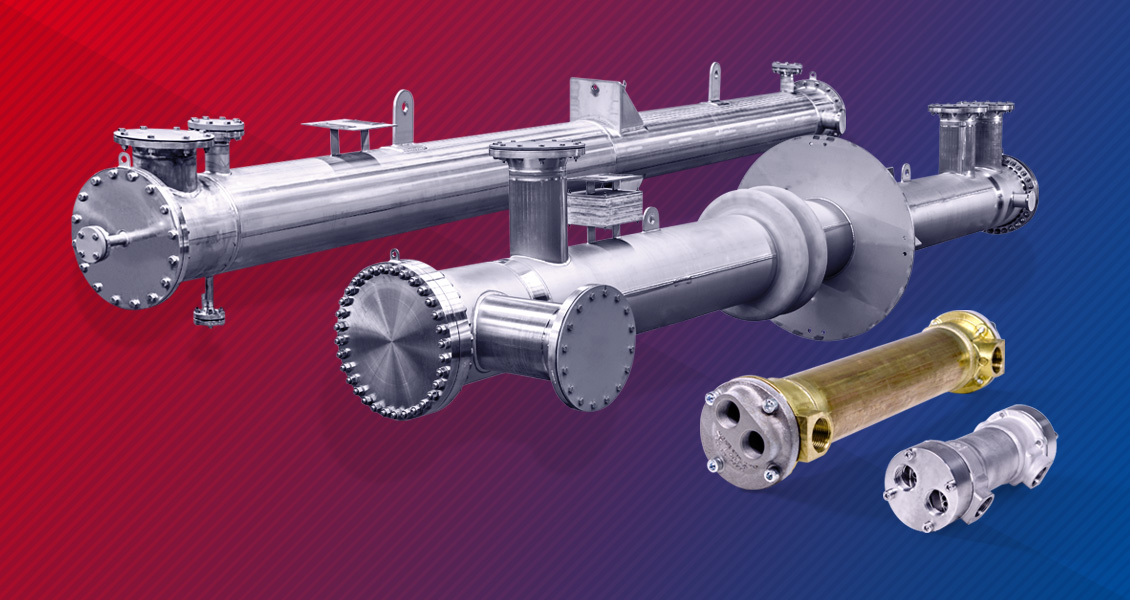

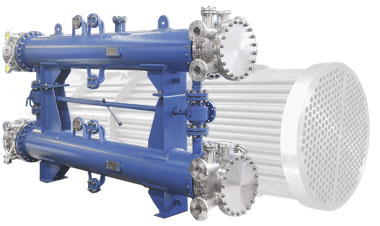

In the area of shell-and-tube heat exchangers, Funke offers a sophisticated range of special models for any requirement in mechanical and plant engineering. Maximum quality and customer-oriented solutions characterise the FUNKE brand

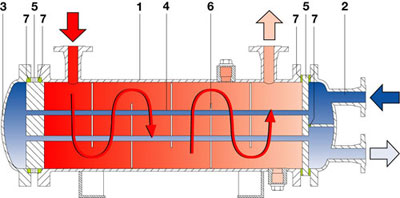

A heat exchanger is an unfired pressure system in which two media flow past one another separated by as thin a wall as possible, so that if there is a temperature difference, they will mutually exchange heat without mixing in the process.

As the diagram shows, one medium flows through the shell chamber and the second medium through the tube chamber. The flow through the shell chamber is controlled by baffles, allowing as much cross flow to the tubes as possible. The form and spacing of the baffles is adapted to the application. Depending on the expediency, speed and pressure loss, the flow through the tube chamber is carried out by a single pass or multiple passes.

With the exception of radiation losses, the input heat quantity is the same as the output heat quantity.

However, an efficient heat exchange can only take place if there is a sufficient temperature difference. The greater the temperature difference, the smaller the required heat transfer surface. This makes a compact apparatus design possible.

The heat transfer performance of a heat exchanger is the product of the mean logarithmic temperature difference, the heat transfer surface and the heat transfer coefficient. The latter is largely determined by the flow characteristic of the media, i.e. by the design features.

On the other hand, the supplier of heat exchangers must have extensive application expertise with regard to the thermodynamic properties of special media at relevant pressures and temperatures. This also applies to the issues of fouling factors and material compatibility.

The calculation and design of FUNKE heat exchangers is carried out with worldwide leading programs (e.g. HTRI, Heat Transfer Research Institute, USA) and with in-house developed software, which is already used around the world.