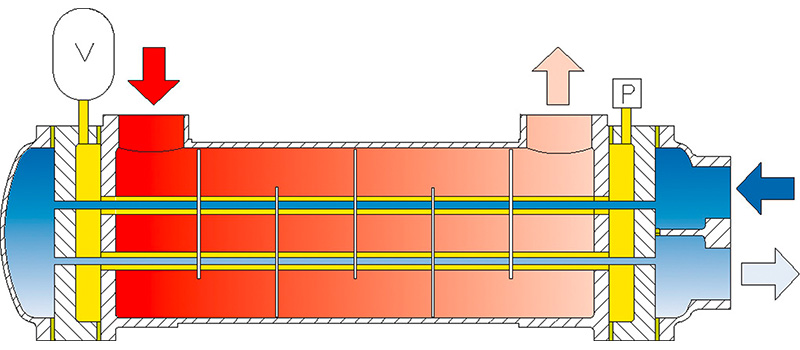

V = volume expansion tank, P = pressure control device, yellow area = safety space

Safety heat exchangers are used wherever the highest requirements for product purity in process engineering (e.g., food/pharmaceutical industry) are required, where there is an environmental risk of contaminating cooling or process water, or because mixing of the media can damage the machine or system.